|

|

|

|

![]()

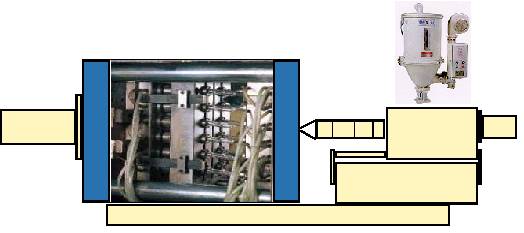

Complete equipment

for manufacturing PET preforms.

Output: up to approx. 5000 pcs./h, depending on preform weight,

cavities and size of injection moulding machine.

PET Preform Injection Moulding Machine >ECON-HS-K3<

Other ancillary Equipment

Injection moulding machine for manufacturing PET materials in special design:

Injection moulding

machine with conformist / different output.

Hopper dryer and granulat dehumidifier for manufacturing PET materials.

Injection moulds with hot runner gate system max. 24 cavities for

fully automatic manufacturing PET preforms.

Water chiller units for process controlling of the complete equipment.

Machine capabilities and approx. capacities in pcs. per hour: |

Model: |

20-26g |

pcs./h |

28 - 32g |

pcs./h |

34 - 40g |

pcs./h |

40 - 48g |

pcs./h |

ECON HS-180 K3 |

12 cavity |

2000 |

12 cavity |

1600 |

8 cavity |

950 |

8 cavity |

720 |

ECON HS-250 K3 |

18 cavity |

3000 |

16 cavity |

2100 |

12 cavity |

1500 |

12 cavity |

1000 |

ECON HS-330 K3 |

24 cavity |

4000 |

24 cavity |

3000 |

18 cavity |

2100 |

18 cavity |

1500 |

ECON HS-360 K3 |

24 cavity |

4000 |

24 cavity |

3000 |

24 cavity |

2800 |

24 cavity |

1900 |

ECON HS-450 K3 |

32 cavity |

5000 |

32 cavity |

4000 |

32 cavity |

3600 |

32 cavity |

2700 |

Model: |

50 - 55g |

pcs./h |

80 - 90g |

pcs./h |

100-130g |

pcs./h |

700-750g |

pcs./h |

ECON HS-180 K3 |

6 cavity |

500 |

4 cavity |

350 |

2 cavity |

160 |

-- |

-- |

ECON HS-250 K3 |

8 cavity |

600 |

6 cavity |

500 |

4 cavity |

300 |

-- |

-- |

ECON HS-330 K3 |

12 cavity |

900 |

8 cavity |

650 |

6 cavity |

450 |

1 cavity |

30 |

ECON HS-360 K3 |

18 cavity |

1300 |

12 cavity |

950 |

8 cavity |

550 |

1 cavity |

30 |

ECON HS-450 K3 |

24 cavity |

1700 |

18 cavity |

1300 |

12 cavity |

800 |

2 cavity |

55 |

Equipment of the injection moulding machine:

Special

designed screw with super performance in moulding PET.

Adjustable multi-step pressure and speed for injection and mould

open/close suitable for precision moulding.

Nitrided screw and barrel ensure long service life.

Screw directly driven by a high torque stepless hydraulic motor.

Easy adjusted pressure and flow proportional valves increase reliabilitiy

and sensitivity.

Auto lubrication system.

Mechanical and electric safety initerlock device.

Linear potentiometer for clamping and screw stroke control.

Microprocessor controller.

Optional languages for control panel available.

위 설비는 독일산으로

당사에서 공급이 가능한 것입니다. 상담을 원하시는 경우,

오른쪽에

있는 ![]() 을 누르시고 메일을

보내 주시면 답변을 드리겠습니다.

을 누르시고 메일을

보내 주시면 답변을 드리겠습니다.

메일 제목 Inquiry for 다음에 Model No를 기재해 주시기 바랍니다. 감사합니다.