1) Blown film line

year of construction 1980

Consisting of:

1 Extruder K 35 F-24 D Drive

13,5 KW

1 Blown Film Die FB 50 - 250,

rotating

1 Die insert ø 150 mm for a

film width of 500 - 700 mm double

lay flat 18-20μ

1 Die car

1 Blower with iris diaphragm

1 Cooling ring KRd 50-300 turnable

+ 1 set of lips of ø 150 mm

1 Film haul-off SFB 1000, effective

width 800 mm

1 Side setting device

1 Film winder FW 1/1, effective

width 800 mm

1 Winding station

Condition: As dismantled from

production

|

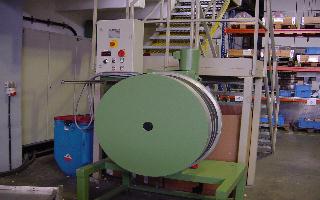

2) 2X Blown Film

Line year of construction 1979

Consisting of:

1 Extruder K 45 F - 24 D Drive

36,9 KW

1 Blown Film Die FB 80-300,

rotating

1 Die insert ø 200 mm for film

width

1 Die car

1 Blower M 16500 with iris diaphragm

1 Cooling ring KRd 50-300 turnable

+ 1 set of lips of ø 200 mm

1 Film haul-off SFB 1000 effective

width 1000 mm

Wooden guiding elements and

water-cooled plates

1 Film winder FW 2/1, effective

width 1000 mm, two winding stations

Drive roll ø 165 DC drive

Condition: As dimantled from

production

|

3) Blown Film Line

KWK - 1400 / 65 HL

Year of construction 2000

Licence construction, mechanical

part

Output:

LD-PE 140-160 kg/h; LD-PE 25

to 150 μ

Film width: 300 - 1400 double

lay flat

Consisting of:

1 Extruder 65-24D; Drive 53,2

KW; Feed block, pressure and

melt temperature gauge

1 Guide block with tubular screen

fitted

1 Blown film die with ø die

insert of LD-PE / LLD-PE

1 stationary cooling ring with

tool insert of 250 mm

1 Cooling blower

1 Heat exchanger

1 Calibration basket, 12 rows,

9 segments

1 Oscilating haul-off, roll

width 1500 mm suitable for 80m/min

1 Film cradle with service platform,

stairs and railing

1 Center wet guiding device

1 Intermediate haul-off with

rolls

1 Edge trim cutting

device

1 Edge and center cutter (3

tape knives)

1 Completely automatically winding

unit (tandem winder, back to

back)

1 Pro-longed film guiding device

Condition: new

|

4) Cooling ring

Saturn 350

Double lip cooling ring

New

|

5) Blown Film die

WV 5/IBC

Year of construction 2000

Test die for inserts 350 to

600 mm

For inner air exchange, stationary

|

6) Film folding

station

STARSEAL (star fold)

|

7) Cable protective

hose line

Year of construction 1999

For the production of hard/soft

PVC pipes (pool pipes)

Extruder KS 60 - 24 D

Extruder KS 45 - 24 D

Double profile head, 2 x plain

tubes

Double spiral machine, 2 winding

mandrals

Tool ø 19 mm

Tool ø 24 mm

Water bath 52 m steel

Central control desk

|

8) Tape production

line, reinforced tapes 2 x 50

and 1 x 100 mm

For the production of reinforced

tapes for pipe strengthening

(PE + Aramid fiber), Belt bands

(PP + Polyester fiber)

Consisting of:

Extruder K 70 - 30 D 81 kW AC

Laminating die FBK 100

Water cooling unit

Basis with blocking and pulling

device (15 KW each)

Yarn heating system / yarn guide

Helping haul-off after the pulling

device

Several tools

Line navigation system

|

9) Conveyor belt

with double chute

Tape width 80 mm

Tape length 2000 mm

Speed max. 50 m/min.

Pneumatic deposit station

|

10) Disk haul-off

K-UM-5022

Diameter of disk 955 mm

Haul-off speed 30 m/min. (1:10)

Drive 2,2 KW

Laboratory machine

Year of construction 1996

메일 또는 전화로 문의주시면

상세 사양 및 견적을 드리도록

하겠습니다.

|