JSTC

![]() Sidel

Stretch Blow Molding Machine

Sidel

Stretch Blow Molding Machine ![]()

Sidel SBO 10/14, setup HOTFILL/REFPET

-

Manufacturing Year: 1988

- Last

Upgrade: 2004

Technical Specification;

-

cavities: 10

- number

of ovens: 14

-

production capacity: 10000 bph

-

voltage/frequency/phase: 380/50/3

Oven;

- oven

banks: 10

- zones:

14

- 2 x

corner lamps: 2 zones

- pitch

of lamps: 15 mm

- power

of lamps: 2000 W

- power

control: pyromat

Special

Features;

- a

ventilated oven

-

oven has been replaced by Sidel in 1994

- quick

change spindles

- quick

change infeed starwheel

- hot

air extraction hood can be mounted above the oven

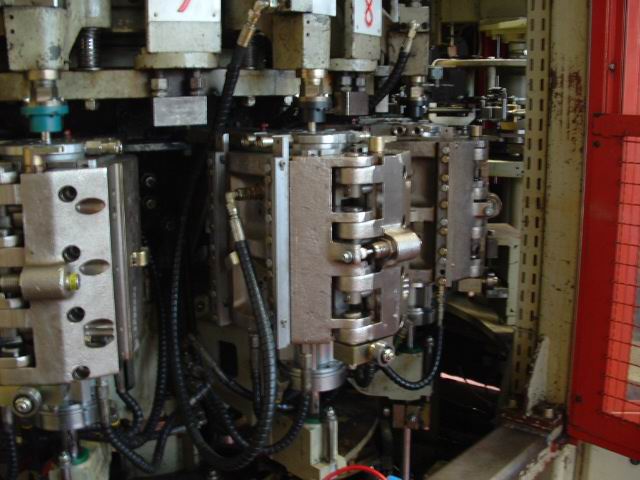

Blow

Wheel;

- GUPM

mold support, new design (all 10 have been replaced in the last 4 years,

including Wentworth Quick Change Mold

System)

- Hot

& Cold Water Circuit, useable for HOTFILL / REFPET

- 15 mm

stretch rods

- quick

change bottle outfeed guiding system and starwheel

-

pneumatic brakes

- DC

currentsrive motor replaced for AC current motor with frequency

converter

Additional Information;

Pressco Vision System (New in

2004); 4 camera system for full waste inspection of 1 L

bottle

Tipper:

- can

handle gaylords 1200x800 mm & 1200x1000 mm

- Height

gaylord (Octabin): 1500 mm

- Hopper

/ Orientor: fitted with a new electrical cabinet

Special

Features;

-

several spare parts

- full

toolset for 38 mm EZ seal preform

- full

toolset for 28 mm REFPET

- full

toolset for 28 mm PCO standard

-

spindle nozzles for 28 mm PCO thick e-wall

- full

toolset for 28 mm PCO middle height (17.5 mm)

Blow

Molds;

- GUPM

quick change cradles from Wentworth for mold shell system 150 mm diameter (200

ml - 1500 ml)

Manual;

- all

manuals are in English, including a CD-ROM will all spare

parts

< Inquiry >

tel: +82 2 2679 6662 info@jstradingco.com fax: +82 2 6230 9192