JSTC

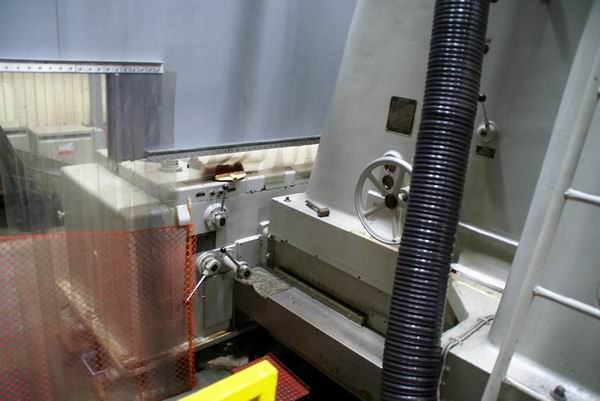

Schiess Vertical Gear Hobbing Machine

Manufacturer:

Schiess

Model RF40/60S

New in

1969

Specifications:

Gear Diameter To Be Hobbed,

Max.: 6096 mm

Gear Diameter To Be Cut, Min.: 1397

mm

Helix Angle Produced, Maximum.: 45 Degree

D.P. Produced By Means oF

Hobs, Max. Finish Worm Drive: 2 DP

D.P. Produced By Means Of Hobs, Max.

Roughing Worm Drive: 1 DP

Min. Vertical dist. Center of swivel to top of

table, Max: 749 mm

Max. Center Distance of Hob to Table: 3099 mm

Min.

Center Distance of Hob to Table: 800 mm

Face Width Of Gear Produced, (Hob

Saddle Travel), Max.: 2540 mm

Table Load Capacity, Max.:

100 Tons

Table Diameter: 4394

mm

Table Spindle Bore Diameter: 1194 mm

Diameter of Indexing Worm

Wheel: 4242 mm

Hob Diameter, Maximum: 337 mm

Hob Spindle On Spline Shank,

OD: 130 mm

Hob Spindle In Front Bearing Diameter: 150 mm

Hob Spindle Bored

To Take Metric Taper: 80

Hob Spindle Speeds: 9 To 100 RPM

Hob Saddle Feed

When Hobbing

(Per Revolution of Table): 0.06096 mm - 8 mm

Column

Feed,(Per Revolution Of Table): 0.127 mm-16 mm

Number Of Feeds: 18

Rapid

Traverse Of Hob Saddle: 203 mm/min

Rapid Traverse Of Column: 457

mm/min

Table Speed For Setting Purposes (Approx): 0.16-0.6 RPM

Main Drive

Motor, Horsepower/RPM: 25 KW/2250 RPM

Rapid Traverse Motor, Horsepower: 11

KW

(2) Coolant Pump Motors, Horsepower: 1 KW

Lube Oil Pump Motor,

Horsepower: 4 KW

Load Relief Table Track Oil Pump Motor: 1 KW

RPM Of These

Motors: 1800 RPM

Machine

Featfures:

* Massively Proportioned Machine Main Base,

Slideways & Hob Column

* Hob Saddle w/Adjustable Bronze Gib Strips

w/Precision Feed Screw w/Built-In Backlash Eliminating Feature

* Duplex Worm

Drive Swivel Hob Head Providing Higher Transmission Ratio At Output Stage, &

Quieter, Smoother Operation w/Axial Adjustment For Reducing Backlash

* Double

Worm Drive To Work Table w/SCHIESS Patented Master Worm Wheel Design (Straight

Spur Steel Coarse Pitch Indexing Wheel, Bronze Master Worm-Gear For

Finishing)

* Duplex Indexing Worms

* Hydraulic, Self-Regulating Table Load

Relief

* Infinitely Variable Feeds, Changeable Under Cutting

* Power

Forced Lubrication System For All Slideways, Bearings & Gear Meshing

Points w/Special Easy Change-Over Filter & Monitored Optical & Acoustic

Warning Signals

* Differential Mechanism For Cutting Helical Gears, Including

Helical Gears w/Large Prime Numbers Of Teeth

* Variable Speed DC Main Drive

Motor w/Reversible Three-Phase Motor For Rapid Traverse Movements

* Full

Complement Of Electics (Motor/Controls), Buss-Ducting, Electrical Switch-Gear

Cabinet, Operator0 ms Control Station/Desk w/Push Buttons For Machine Inching

Motions, Set Up, & Fault Lamp Indication For Lube And/Or Coolant

Failure

Machine Equipped

With:

* Operator's Moveable Hand Held Pendant

Control

* Complete Coolant Plant, Pump, Tank & Piping w/Magnetic Chip

Conveyor & Discharge Tub

* Large Assortment Of Change Gears For Index,

Differential, Including Primes

* Large Assortment Of Hob Arbors

* HIGH

ACCURACY HOBBING HEAD

* HIGH ACCURACY SHAVING HEAD

* Miscellaneous Tooling

and fixtures (yellow fixture in photo not

included)

* Operator's Manual, Wiring & Hydraulic Diagrams,

Foundation Drawings, Etc.

< Inquiry >

tel: +82 2 2679 6662 info@jstradingco.com fax: +82 2 6230 9192